/ Electronics

ELECTRONIC SOLUTIONS

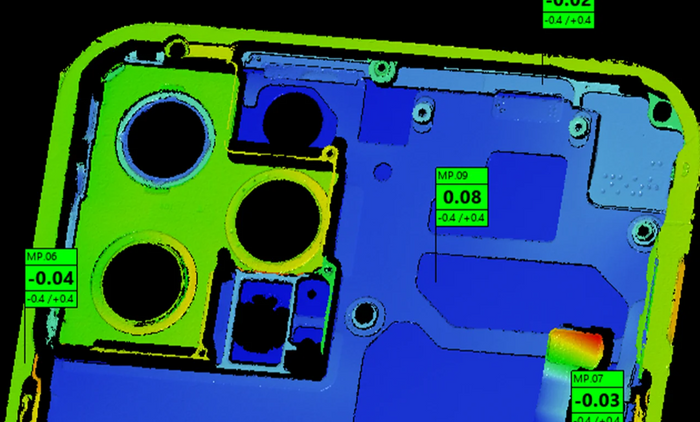

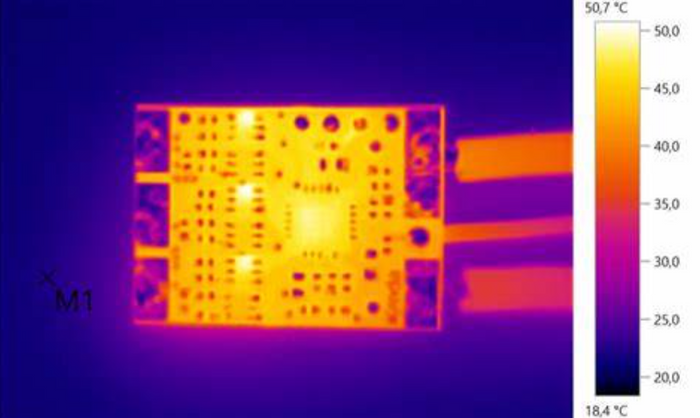

Thermography plays a pivotal role in electronics manufacturing due to its ability to detect temperature variations invisible to the naked eye. It ensures product reliability by identifying faulty connections, overheating components, or potential malfunctions before they compromise the final product.

Swift in-line and non-intrusive testing of circuit boards aids in quality control. By assessing thermal performance, design improvements for better heat dissipation and overall efficiency can be made. Thermography's role extends to monitoring temperature-sensitive processes, optimizing manufacturing conditions, and ultimately ensuring the production of high-quality, reliable electronic devices.

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal distribution of letters, as opposed to using 'Content here, content here', making it look like readable English.

Many desktop publishing packages and web page editors now use Lorem Ipsum as their default model text, and a search for 'lorem ipsum' will uncover many web sites still in their infancy.

Key Features:

Key Advantages:

-

Quality Assurance: It identifies faulty components or connections by detecting abnormal heat signatures, ensuring the quality and reliability of electronic assemblies.

-

Fault Detection: Thermography reveals overheating components or areas prone to failure, allowing for preemptive action before malfunctions occur.

-

Efficient Testing: It enables quick, non-contact testing of electronic devices and circuit boards, streamlining quality control processes.

-

Design Improvement: Helps in refining designs by assessing thermal performance, optimizing heat dissipation, and enhancing overall product efficiency.

-

Process Optimization: Allows for monitoring temperature-sensitive manufacturing processes, ensuring proper execution and preventing defects during production.

-

Holistic Monitoring: Thermography simultaneously monitors multiple areas, offering a comprehensive view, unlike discrete sensors focusing on specific points.

-

Non-Invasive Inspection: Thermography evaluates electronics without physical contact, while discrete sensors may require attachment or alteration.

-

Real-Time Monitoring: Thermography provides continuous, immediate anomaly detection, unlike discrete sensors with limited or intermittent data capture.

-

Efficient Scanning: Infrared cameras swiftly scan larger areas, speeding up inspections compared to placing discrete sensors individually.

-

Detailed Analysis: Thermography offers detailed thermal imaging for better temperature visualization, whereas discrete sensors provide point-specific data.

Call

Follow

123-456-7890