/ Metallurgy / Slag Detection

SLAG DETECTION

Heat Eyes slag detection systems revolutionize metal quality enhancement and treatment cost reduction by curbing slag carryover during tapping processes.

These systems boast a robust setup: a thermal camera housed in protective enclosures, dedicated imaging software, comprehensive database storage, a user-friendly interface, and status-indicating devices.

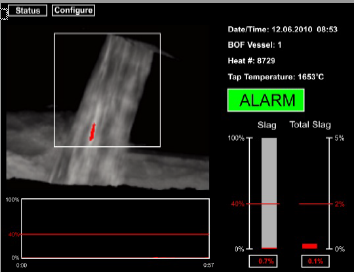

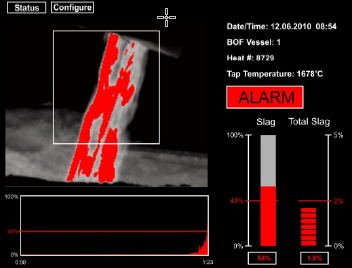

During tapping, the thermal camera monitors the pour stream, accurately distinguishing between liquid metal and slag due to distinct radiation properties. This real-time assessment enables precise slag transfer calculation, triggering an alarm when the preset content threshold is reached, halting the tap.

Critical data, from live thermal images to slag content versus tap time, is intuitively displayed for immediate analysis. The powerful database automatically stores thermal images and process parameters, enabling extensive post-process analysis and intranet connectivity.

Engineered for relentless 24/7 operation in harsh smelting environments, these systems feature self-diagnostic functions, intelligently resolving most malfunctions without user intervention. Encased in robust housings cooled by water, the thermal camera's protective window remains contaminant-free through air barrier mechanisms, ensuring unwavering reliability.

Key Features:

Key Advantages:

-

Seamless, fully automated measurements

-

Complete traceability: Automatically stores slag transfer, tap data, and images

-

Cutting-edge data management and tap analysis via a database and web server

-

Versatile interfaces for streamlined process control and visualization

-

Robust, fail-safe design ensuring uninterrupted operation in steel plants

-

Elevates steel quality standards

-

Boosts production yields significantly

-

Slashes treatment expenses

-

Accelerates processing timelines