/ Metallurgy / Ladle Monitoring

LADLE MONITORING

Heat Eyes ladle check refractory monitoring systems enhance safety and streamline maintenance schedules in metallurgical processes. These systems minimize the risk of molten steel breakouts while prolonging the refractory lining's lifespan, offering two significant benefits: increased safety for plants and significant cost reductions.

Liquid metal breakouts from flawed ladle refractory linings pose dangers in metals production, resulting in equipment damage, high repair costs, and production delays.

Heat Eyes' integrated solution actively prevents such breakouts by continuous monitoring, detecting defects or depletions before they escalate.

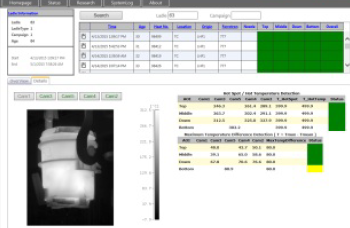

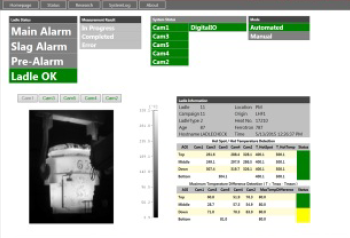

By extending refractory lifespan, these solutions optimize maintenance schedules, maximizing heats without compromising safety. Thermal imaging cameras, part of Heat Eyes' modular system, measure ladle surface temperatures during transport without interrupting crane operations.

Analysis of this data informs crane operators of the ladle's condition, stored for comprehensive refractory status analyses. Heat Eyes systems revolutionize steel production by ensuring safety, reducing operational costs, and providing detailed insights for efficient refractory maintenance.

Key Features:

Key Advantages:

-

Liquid steel breakout prevention

-

Early wear area identification

-

Cost-effective: Maximizes refractory lifespan safely

-

Enhanced maintenance strategy

-

Heightened safety in steel production

-

Refractory lining efficiency comparison

-

Fully automated, operator-free measurements

-

Scalable to any number of thermal cameras

-

Complete traceability: Stores images, temps, and process data

-

Advanced data analysis via database and web server

-

Versatile interfaces for process control integration