/ Petrochemical / Gasifier Monitoring

GASIFIER MONITORING SOLUTIONS

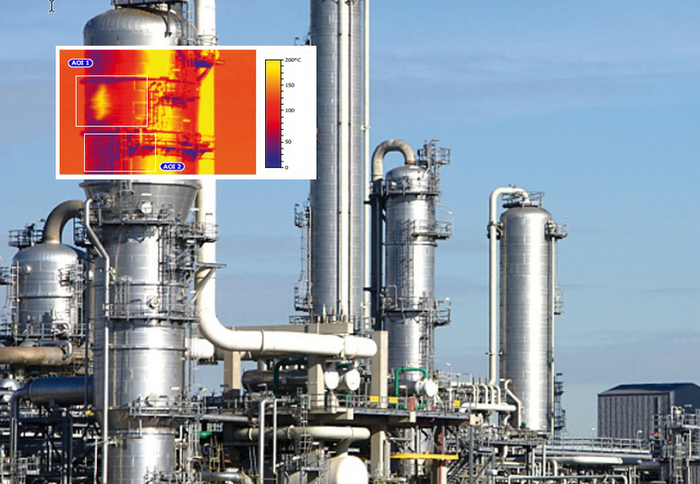

Gasifiers facilitate the conversion of carbon-containing materials like coal or oil into synthesis gas. Operating at temperatures up to 1600°C and high pressures, these inner processes demand a fireproof lining within the reactor vessel. Over time, the refractory endures wear, cracks, and degradation.

A failure in this lining could prompt the hot gas to breach the metal shell, causing a potentially catastrophic explosion and unplanned shutdown. Apart from the economic impact, such failures pose severe risks to personnel safety. Hence, ensuring the gasifier's safe operation necessitates constant, reliable monitoring of the refractory lining's condition.

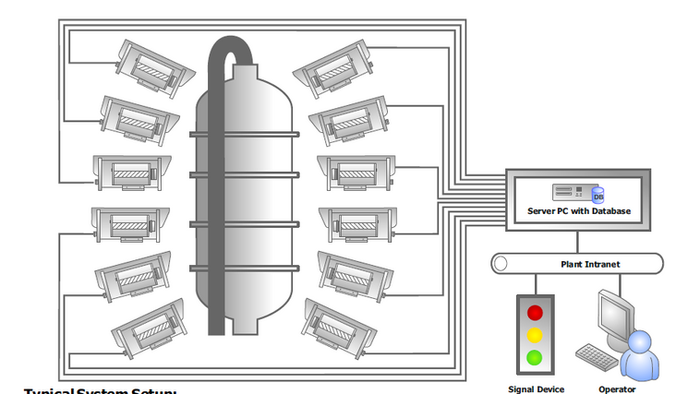

Infrared imaging systems offer an effective solution for monitoring gasification vessel temperatures. Continuous scanning by infrared cameras swiftly identifies and tracks hotspots or unusual thermal conditions, preempting threats to reactor metallurgy.

Beyond safety, thermographic monitoring serves as a valuable tool for process optimization. Analyzing thermal images aids in pinpointing the reaction zone, assessing refractory wear, and detecting alterations in feed injector performance. Therefore, our thermographic monitoring system delivers both safety assurance and economic advantages, ensuring optimal operational efficiency.

Key Features:

Key Advantages: